Efficiently rotate and pick inventory with Carton Flow racks. You can easily handle the intake of goods with bulk sorting capabilities while getting them out faster than they can come in. The process of intaking goods and organizing them will both save time when picking and reduce errors made.

Pair this concept with pick-to-light technology and you have a recipe for success. Each item can be scanned when inducted into the processing area, illuminated, and then placed into large sorting containers. Once bulk sorted, each individual item can be scanned into their own bin on the carton flow rack for easy picking. This removes the manual error of trying to find the right container and allows for each item to be placed in the correct stocking order.

Sorting and Stocking Methods

There are different strategies to implement when stocking or rotating your inventory. Most popular, is “First-in, First-out” and “Last-in, First-out”.

“First-in, First-out” refers to the order that goods are placed in the picking order. Items that are placed first will be taken first, with the items behind them rotating forward. This allows for inventory to be sorted easier, as well as speeding up picking time.

“Last-in First-out” storage differs as the items are stocked so the last item placed is the first to be grabbed out. Generally, this application is for items that are less time sensitive.

Overall Benefits

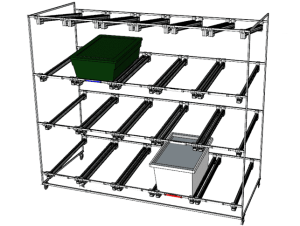

Regardless of how your team stocks and picks, one benefit of carton flow racks is how they can create lanes. Instead of having one central walkway, each side of the rack can be easily designated for a purpose; meaning that one path is specific to loading and stocking, while the lane for picking has a lot less congestion.

Carton Flow has an increasingly beneficial prospect to eCommerce and other fulfillment services. Overall efficiency is improved due to the increased stocking speed, smaller footprint, and reduced movement needed. Even last mile couriers and other package delivery services can utilize Carton Flow racks.

Racks can be configured with various container sizes and be able to contain numerous items, allowing for systems that can adapt when needed. One of the more common configurations is a series of gravity-fed rollers, which can move and widen to fit totes or containers of any size. An important consideration when deciding on carton flow racks is your containers. To effectively function, you must have containers that are easily pickable and can hold up over time. This means that you may need to think about how much your container weighs; if the items can be evenly displaced, and what materials your containers are made of.

Check Out our Solutions

Our pick-to-light solution, the LightSort Sorting System, can be adapted and modified to fit various environments. Whether you need a Gravity Fed system, package sorting solution, or anything in between our technology can be applied to increase efficiency. We can even retrofit existing racks with our light technology to ease the sorting and picking process.

At Engineering Innovation, we aim to create custom solutions that will offer you the right fit for your operation. We can create concepts and help solve problems in your warehousing operation with our over 15 years of experience. If you would like to learn more or are interested in consultation, fill out our form below.